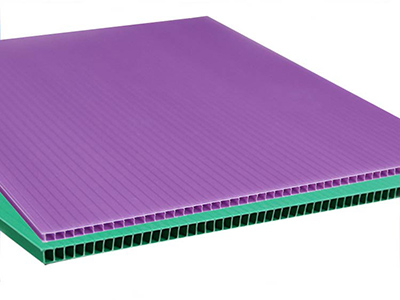

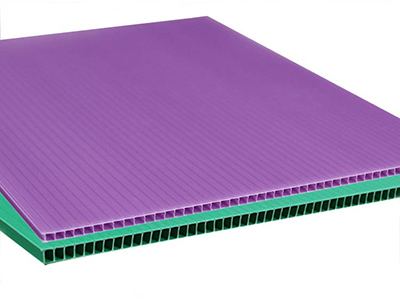

The scientific name of pp hollow board is polypropylene hollow board. Its raw material PP is another excellent resin variety developed after nylon. It is a linear polymer with high density, no side chains, and high crystallinity. Comprehensive performance. PP has good resistance to solvents, oils, weak acids and weak alkalis. Polyoxymethylene has high hardness and rigidity, high resistance to creep and stress relaxation, excellent wear resistance, self-lubrication, and fatigue, which cannot be compared with other engineering plastics.

The processing temperature (℃) during the production of polypropylene is 180~240. So boiling water will not decompose it, and it is a semi-crystalline material. The raw material of PP hollow board is harder than PE and has a higher melting point. Since homopolymer PP is very brittle when the temperature is higher than 0℃, many commercial PP materials are random copolymers with 1 to 4% ethylene or clamp copolymers with higher ethylene content.

Copolymer PP material has lower thermal distortion temperature (100℃), low transparency, low gloss, low rigidity, but has stronger impact strength. The strength of PP hollow board increases with the increase of propylene content. The Vicat softening temperature of PP is 150°C. Due to the high crystallinity, the surface stiffness and scratch resistance of this material are very good. PP hollow board does not have the problem of environmental stress cracking. Usually, the PP is modified by adding glass fiber, metal additives or thermoplastic rubber.

The flow rate MFR range of PP hollow board is 1~40. PP materials with low MFR have better impact resistance but lower tensile strength. For materials of the same MFR, the strength of the copolymer type is higher than that of the homopolymer type. Due to crystallization, the shrinkage rate of PP is quite high, generally 1.8~2.5%. And the directional uniformity of shrinkage is much better than that of PE-HD and other materials. Adding 30% of glass additives can reduce the shrinkage to 0.7%. Both homopolymer and copolymer PP materials have excellent moisture absorption, acid and alkali corrosion resistance, and solubility resistance. However, it has no resistance to aromatic hydrocarbon (such as benzene) solvents, chlorinated hydrocarbon (carbon tetrachloride) solvents, etc.

PP hollow board does not have oxidation resistance at high temperature like PE. Polypropylene (PP) is the lighter one among the common plastics. It has excellent electrical properties and can be used as a high-frequency insulation material resistant to humidity and heat.

PP is a crystalline polymer. When the melt is condensed, due to the large change in specific volume and high degree of molecular orientation, it shows a large shrinkage rate (1.0%-1.5%). In the molten state of PP, heating up to reduce its viscosity has little effect. Therefore, in the molding process, the injection pressure and shear rate should be increased mainly to improve the molding quality of the product.